A bulletproof vest, also known as a ballistic vest, is a critical piece of personal armor designed to protect individuals from firearm projectiles and shrapnel.

The effectiveness of bulletproof vests depends largely on the materials used in its construction.

Manufacturers make vests from a combination of advanced fibers and hard plates, typically ceramic or steel, which provide additional protection.

These materials work together in layers to absorb and distribute the energy from bullets, ensuring the wearer’s safety in dangerous situations.

Let us talk about it in greater detail.

Table of Contents

ToggleMaterials Used in Bulletproof Vests

Bulletproof vests rely on a range of advanced materials that strike a balance between strength, flexibility, and weight, ensuring optimal protection against various types of ballistic threats.

Manufacturers carefully select these materials based on their ability to absorb and disperse energy, their durability in different environments, and their overall wearability.

Let’s check them out:

| Material | Key Properties | Usage | Advantages |

|---|---|---|---|

| Kevlar | Strong, flexible, lightweight | Soft body armor | Flexible, durable, heat and chemical resistant |

| Dyneema | Stronger than steel, lightweight, chemical resistant | Soft and hard body armor | Stronger than Kevlar, highly durable |

| Spectra | Lightweight, excellent ballistic protection | Primarily in soft body armor, sometimes layered with hard plates | Light, high impact resistance, long-lasting |

| Steel | Heavy, highly durable | Hard body armor | Durable, stops high-caliber rounds |

| Ceramic | Lightweight, dissipates energy on impact | Hard body armor plates | Lightweight, great for high-velocity rounds |

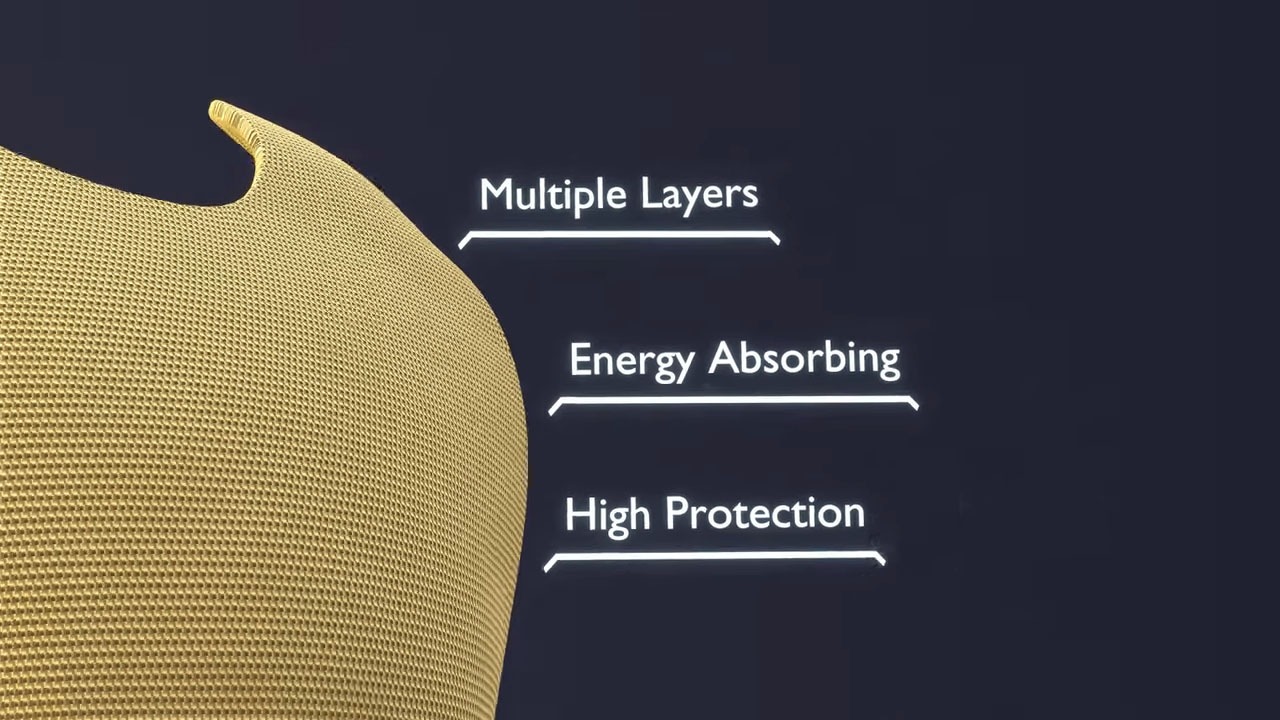

Layered Construction of Bulletproof Vests

The effectiveness of bulletproof vests depends not only on the materials they use but also on their layered construction, which absorbs and distributes the force of ballistic impacts.

Manufacturers typically construct the outermost layer, or outer shell, from abrasion-resistant materials such as nylon or polyester.

- Kevlar

- Dyneema

- Spectra

These fibers are densely woven or laminated to create a surface capable of absorbing the energy from a bullet. When a projectile strikes the vest, these layers deform and spread the force over a larger area, preventing penetration.

To further reduce the risk of injury, many vests include a trauma reduction layer. While the ballistic layers prevent penetration, the trauma reduction layer ensures that the force of the impact does not cause significant injury.

Finally, the backing material provides structural integrity to the entire vest.

It is a layer prevents the ballistic materials from shifting or deforming under the impact of a projectile, ensuring that the vest maintains its protective capabilities even after a strike.

The combination of these layers allows modern bulletproof vests to offer a high level of protection while remaining flexible and comfortable to wear.

Manufacturing Process of Bulletproof Vests

The production of a bulletproof vest follows several precise steps to transform the materials into highly effective and reliable protective gear.

Manufacturers begin by creating raw materials. They spin these materials into fibers that form the backbone of the vest’s ballistic properties.

These fibers provide the strength necessary to stop high-velocity projectiles.

1. Raw Material Production

- Materials Used: Kevlar, Dyneema, Spectra.

- Process: These high-performance fibers are spun into threads, which are then prepared for further processing. These threads are known for their exceptional strength and durability, which are crucial for stopping bullets.

2. Weaving the Fibers

- Weaving Process: The spun fibers are woven into ballistic sheets using specialized machines.

- Result: The weaving process creates a dense, tightly packed structure capable of absorbing and dispersing the energy from bullets. This tight weave ensures that the ballistic material can stop projectiles effectively.

3. Cutting and Shaping the Sheets

- Cutting: Technicians cut the ballistic sheets into specific shapes that correspond to the vest’s design.

- Customization: They tailor each cut sheet to protect key areas of the body, such as the chest, back, and sides.

4. Layering and Assembly of Protective Panels

- Layering: Manufacturers sew or bond multiple layers of ballistic material together to create the protective panels.

- Customization of Protection: You can adjust the number of layers based on the desired level of protection.

- Encapsulation: Manufacturers seal the panels in waterproof covers to protect them from environmental factors like moisture, dirt, and wear.

5. Carrier Assembly

- Carrier Creation: Manufacturers insert the ballistic panels into carriers, which they make from durable fabrics like nylon or polyester.

- Fit and Comfort: The carriers feature adjustable straps and padding, designed to ensure a snug and comfortable fit for the wearer.

- Final Touches: Designers can add additional features, such as pockets for hard plates or modular attachments, depending on the intended use of the vest.

This manufacturing process ensures that bulletproof vests provide reliable protection while remaining comfortable and practical for everyday use.

Technological Enhancements in Bulletproof Vests

Over the years, bulletproof vests have seen significant improvements, thanks to advancements in technology.

These innovations have enhanced the level of protection, comfort, and functionality that modern body armor offers.

Key technological enhancements include:

| Enhancement | Description | Impact |

|---|---|---|

| Hard Plates for Rifle Protection | Addition of ceramic or steel plates for high-velocity rifle rounds | Enables protection against more powerful projectiles |

| Stab and Spike Protection | Layers designed to resist punctures from sharp objects like knives and spikes | Versatile protection against both ballistic and sharp threats |

| Multi-Hit Capability | Vests engineered to withstand multiple impacts without losing integrity | Crucial for sustained threats, ensuring ongoing protection |

| Lightweight, Flexible Materials | Use of materials like UHMWPE for lighter and more comfortable vests | Enhanced wearability without sacrificing protective capability |

Summary

Manufacturers use advanced materials like Kevlar, Dyneema, and ceramic to create bulletproof vests that provide protection against ballistic threats.

The layered construction and technological enhancements ensure that modern vests are effective, durable, and comfortable.

The safety of users will continue to improve, highlighting the importance of ongoing research and testing in the field of ballistic protection.

Related Posts:

- Long, Fascinating, and Fruitful History of the…

- Is It Illegal to Wear a Bulletproof Vest in Texas in 2025?

- Real-Life Cases Where Police UAV Made a Difference

- Bayraktar TB2 - The Drone That Made History

- What to Know About Physical Fitness Requirements for…

- Gunshot Wound Care - What You Need to Know to Save a Life